Cutting-edge technology

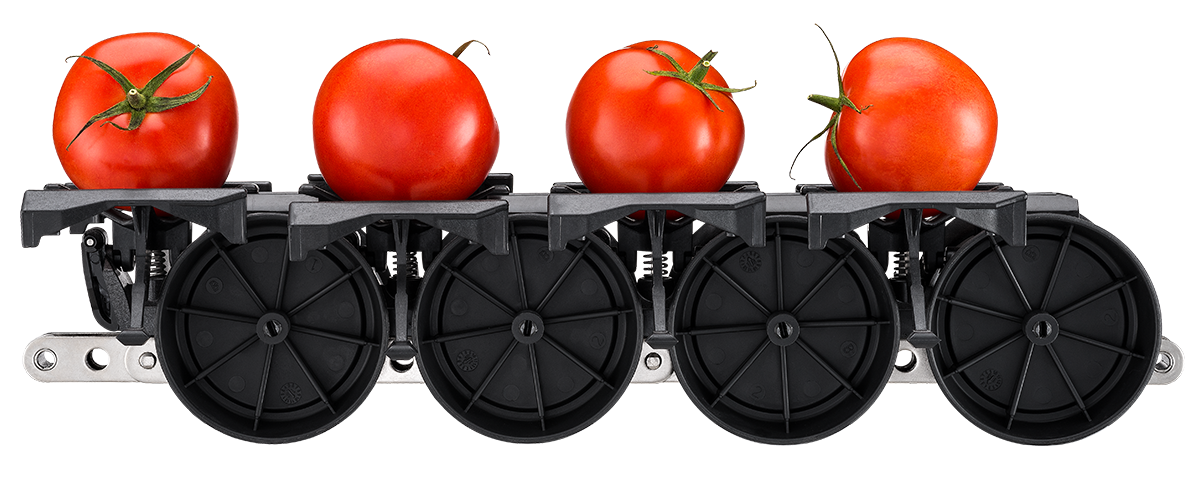

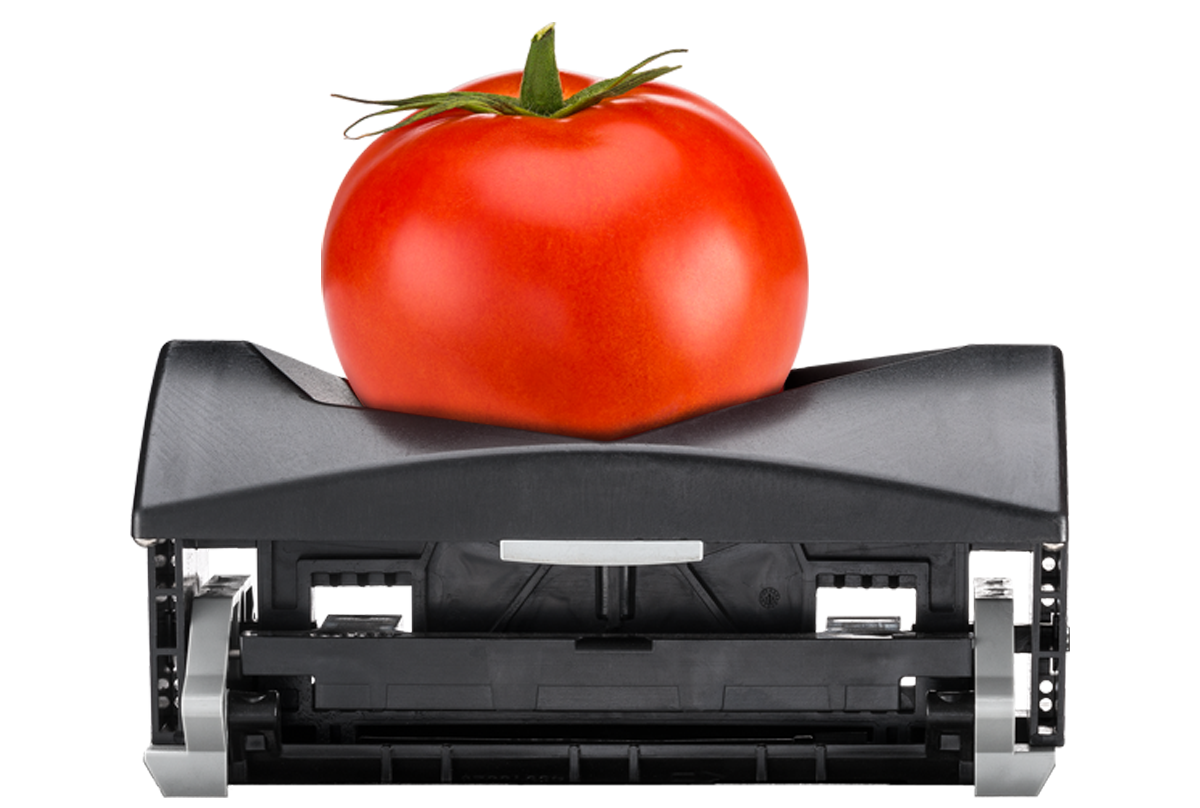

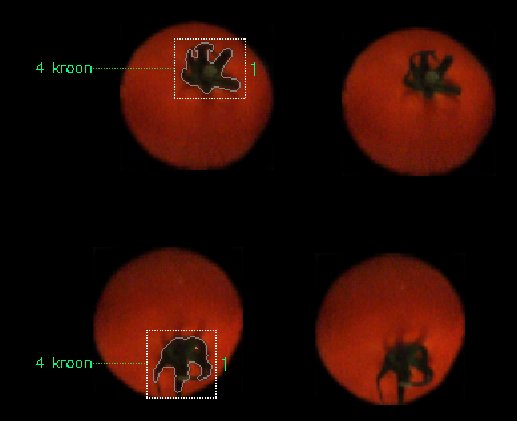

Tomato sorting machine

We have a perfect understanding of your product, market and the specific wishes of your customers and are able to translate your requirements into an innovative tomato sorting and packing solution. We do this based on more than 55 years of experience with in-house sorting and packing technology.